Advanced Woodworking Techniques Using INCRA Miter Gauges

1. Introduction

Precision is the cornerstone of advanced woodworking. Whether you're crafting intricate furniture or detailed joinery, achieving accurate angle cuts is essential. This level of precision requires the right tools, and that's where the INCRA miter gauge comes into play. Known for their superior accuracy and innovative design, INCRA miter gauges are a favorite among professional woodworkers and serious enthusiasts alike.

In this article, we'll explore advanced woodworking techniques that leverage the unique capabilities of INCRA miter gauges. By the end, you'll have a deeper understanding of how these tools can elevate your woodworking projects to a new level of precision and quality.

2. Understanding the INCRA Miter Gauge

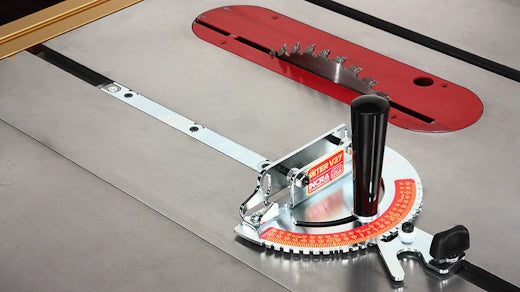

A miter gauge is a critical tool used to guide wood through a saw blade at a specific angle. While most miter gauges allow for basic angle adjustments, INCRA miter gauges stand out due to their exceptional precision and versatility. These gauges are equipped with advanced features like incremental angle adjustment and repeatable accuracy, making them ideal for complex woodworking tasks.

One of the standout features of INCRA miter gauges is their patented GlideLOCK miter bar, which ensures a snug, wobble-free fit in the miter slot. This eliminates the common issue of play in the bar, which can lead to inaccuracies in the cut. Additionally, INCRA miter gauges often include laser-cut V-stops that provide positive angle positioning for the most common angles, ensuring quick and precise setups.

Compared to other miter gauges on the market, INCRA offers a level of precision that is unmatched, making them the go-to choice for woodworkers who demand the highest standards in their work.

3. Choosing the Right INCRA Miter Gauge for Your Project

INCRA offers a range of miter gauges, each designed to meet specific needs and project requirements. Whether you're working on fine furniture or large-scale cabinetry, there's an INCRA miter gauge that will fit your needs perfectly.

The INCRA V27 is an excellent choice for woodworkers who require basic precision. It offers 27 angle stops and is ideal for general-purpose use. For those seeking greater versatility, the INCRA V120 offers 120 positive stops in 1-degree increments, making it suitable for more complex angle setups.

For the most demanding projects, the INCRA 1000HD and INCRA 5000 miter gauges provide the ultimate in precision. The 1000HD offers 180 positive stops in 1/10th-degree increments, while the 5000 combines a miter gauge and sled system to handle larger panels with ease.

When choosing the right miter gauge, consider the complexity of your projects and the level of precision required. Matching the gauge to your specific tasks will ensure that you get the most out of this indispensable tool.

4. Setting Up the INCRA Miter Gauge

Proper setup and calibration are critical to unlocking the full potential of your INCRA miter gauge. While these tools are designed for precision, their accuracy is only as good as their setup. Here’s how to ensure your miter gauge is perfectly calibrated for your woodworking projects.

Initial Setup and Calibration: Begin by attaching the miter gauge to your table saw. Ensure the miter bar fits snugly into the miter slot with no lateral movement. Use the adjustment screws on the GlideLOCK miter bar to achieve a perfect fit, eliminating any play that could affect the accuracy of your cuts.

Ensuring Accuracy: Tips and Tricks: Once the miter gauge is securely in place, it’s time to check the angle settings. Use a reliable digital angle finder or an accurate combination square to verify that the miter gauge is set precisely at 0 degrees. Make adjustments as necessary. For other common angles, such as 45 degrees, repeat this process to ensure each angle stop is correctly calibrated.

Adjusting the Fence for Specialized Cuts: INCRA miter gauges often come with adjustable fences that can be extended or retracted to suit your cutting needs. For specialized cuts, such as compound miters, you may need to adjust the fence to provide better support for your workpiece. This is particularly useful when working with larger panels or when you need to make cuts at non-standard angles.

5. Advanced Woodworking Techniques with INCRA Miter Gauges

The real value of INCRA miter gauges comes into play when you begin exploring advanced woodworking techniques. These gauges are designed to handle complex cuts with unmatched precision, making them invaluable for high-level projects.

Creating Precise Miters and Bevels: One of the most common uses of a miter gauge is cutting miters and bevels. With INCRA's micro-adjustment features, you can dial in the exact angle you need, ensuring tight, seamless joints. This is especially important in projects like picture frames or decorative moldings, where any imperfection would be noticeable.

Techniques for Compound Angle Cuts: Compound angle cuts, where two angles are cut simultaneously, are notoriously difficult but essential in advanced woodworking, especially in projects like custom cabinetry or complex joinery. The precision stops and adjustment capabilities of INCRA miter gauges make these cuts more manageable, allowing you to achieve perfect results every time.

Using the Miter Gauge for Repetitive Cuts: When you need to make multiple identical cuts, INCRA miter gauges excel. The incremental angle settings and repeatability features allow you to set up your cuts once and then repeat them with consistency. This is particularly useful in production environments or when crafting multiple pieces that must match perfectly.

Enhancing Accuracy with INCRA’s Micro-Adjustment Features: One of the standout features of INCRA miter gauges is the micro-adjustment capability. This feature allows you to fine-tune your angles with precision, ensuring that even the most complex cuts are executed flawlessly. Whether you’re working with intricate joinery or need to make small adjustments to fit, INCRA’s micro-adjustment gives you the control you need to get it right.

6. Integrating the INCRA Miter Gauge with Other Tools

To fully harness the power of the INCRA miter gauge, it’s important to integrate it effectively with other tools in your workshop. By doing so, you can take on more complex projects and achieve higher levels of precision and efficiency.

Combining the Miter Gauge with Table Saws for Complex Projects: When paired with a high-quality table saw, the INCRA miter gauge becomes a versatile tool for tackling complex projects. For example, when building custom furniture, the ability to make accurate angled cuts is crucial. The miter gauge ensures that every cut is consistent and precise, which is essential for pieces that must fit together perfectly.

Using INCRA Miter Gauges in Conjunction with Router Tables: Router tables are often used for detailed edge work and joinery. By using an INCRA miter gauge on your router table, you can achieve precise, repeatable cuts that are difficult to accomplish freehand. This is particularly useful for tasks like creating perfect box joints or dovetails, where accuracy is paramount.

Best Practices for Integrating with Jigs and Sleds: Jigs and sleds are commonly used in woodworking to enhance accuracy and safety. The INCRA miter gauge can be integrated with these tools to further improve the precision of your cuts. For instance, a crosscut sled combined with an INCRA miter gauge can provide additional support for larger workpieces, reducing the chance of errors and making your workflow more efficient.

FAQs

1. How do I choose the right miter gauge for my needs?

Choosing the right miter gauge depends on the complexity of your projects and the level of precision required. For general use, the INCRA V27 is a good choice, while the 1000HD or 5000 models are better suited for more demanding tasks that require advanced features and greater precision.

2. What are common mistakes to avoid when using a miter gauge?

Common mistakes include improper setup, not regularly calibrating the gauge, and failing to secure the workpiece properly. Always ensure your miter gauge is tightly fitted to the miter slot and check angles with a square or angle finder before cutting.

3. Can I use an INCRA miter gauge with any table saw?

INCRA miter gauges are designed to be compatible with most standard table saws. However, it’s important to check the miter slot dimensions of your saw to ensure a proper fit. INCRA miter gauges are adjustable to fit a variety of slot sizes.

4. What is the best way to ensure consistent accuracy with my miter gauge?

Consistent accuracy can be achieved by regularly calibrating your miter gauge, maintaining it properly, and using test cuts on scrap wood before committing to your final piece. Using the micro-adjustment feature also helps fine-tune your cuts.

5. How do INCRA miter gauges compare to other brands in terms of durability?

INCRA miter gauges are known for their durability and precision. Made from high-quality materials, they are built to withstand heavy use while maintaining their accuracy. Regular maintenance will ensure they last for many years.