Description

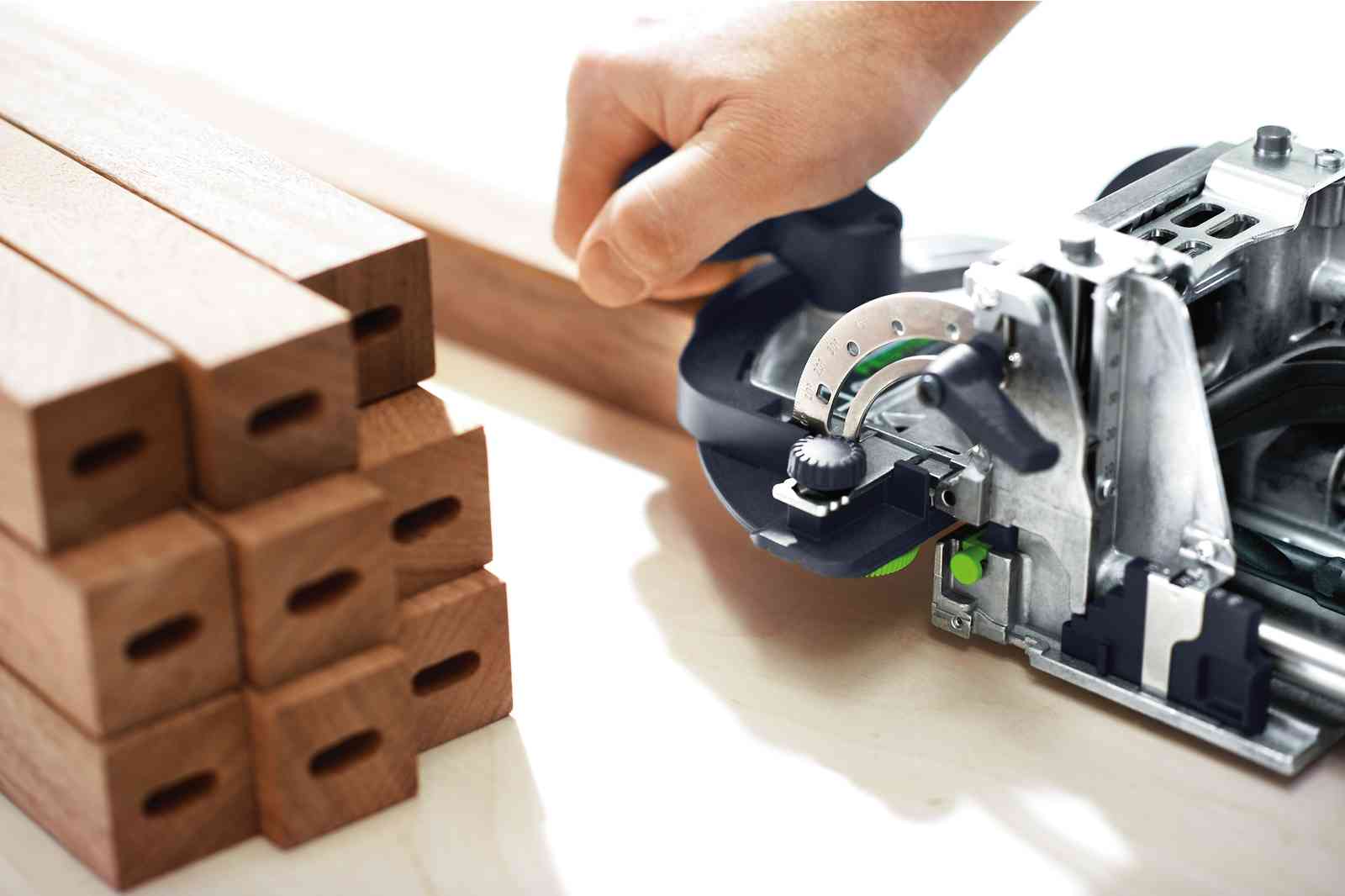

Comes to the workpiece and not vice versa: DOMINO XL. Quick, simple, precise and extremely stable - with measurably shorter tooling times and up to 50% time-saving in comparison to stationary machines. The DOMINO XL is therefore ideally suited for furniture and door construction and solid wood joints.

- Maximum stability of joints up to a DOMINO size of 14 x 140 mm

- Patented routing principle unique to hand-held machines for accurate work with no kickbacks

- Saves more time compared to a stationary machine

- Stops that are quick and easy to adjust, for accurate results

- System accessories compatible with both DOMINO jointers

Technical Data

| Power consumption | 720 W |

| Idle engine speed | 21 000 min⁻¹ |

| Depth stop for routing depth | 15 - 70 mm |

| Max. routing depth | 70.00 mm |

| DOMINO slot cutter dia. |

8, 10, 12, 14 mm

|

| Routing height adjustment | 10 - 50 mm |

| Mitre routing | 0 - 90 ° |

| Dust extraction connection diameter | 27 mm |

| Cable length | 4.00 m |

| Product weight | 5.50 kg |

| transportgewicht | 10.20 kg |

| Drive type | Mains |

Includes

DOMINO cutter D 12

Additional stop

empty dowel box

open ended spanner, WAF 12

Systainer SYS3 M 437